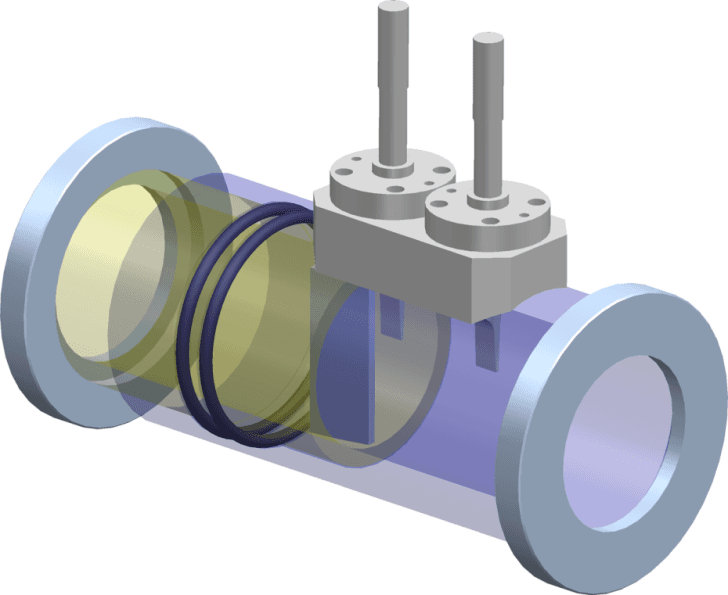

Vortex Cross-correlation Flowmeter

Indian Patent No - 1763/MUM/2013 (Granted)

Background: Vortex flowmeters are extensively used in various industrial applications for fluid flow measurement. The performance of vortex flowmeters is significantly compromised by various factors inherent to industrial processes, such as flow pulsations, piping vibrations, and installation effects. These factors attract significant concern, particularly when operating under low Reynolds number flow conditions, where the vortex signal is relatively weak. Consequently, these effects impose limitations on the flowmeter's lower operating range.

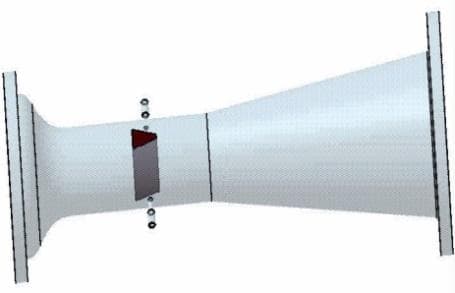

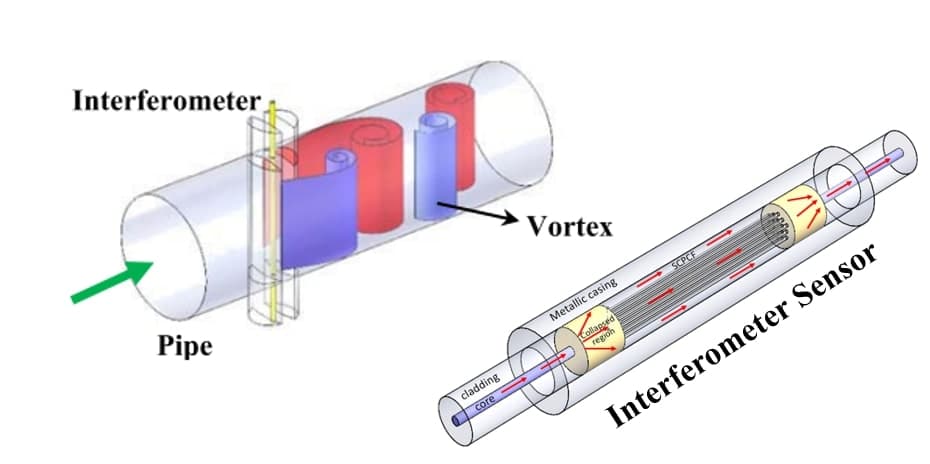

Vortex Flowmeter for Measuring a fluid flow rate

Indian Patent No - 2459/MUM/2015 (Granted)

Background: Vortex flowmeters are widely employed in industrial applications to measure fluid flow. However, their performance is greatly affected by factors like flow pulsations, piping vibrations, and installation effects. Hence upstream and downstream straight pipes are required to achieve the required accuracy. However, this piping requirement is expensive and may not be feasible in industrial applications.

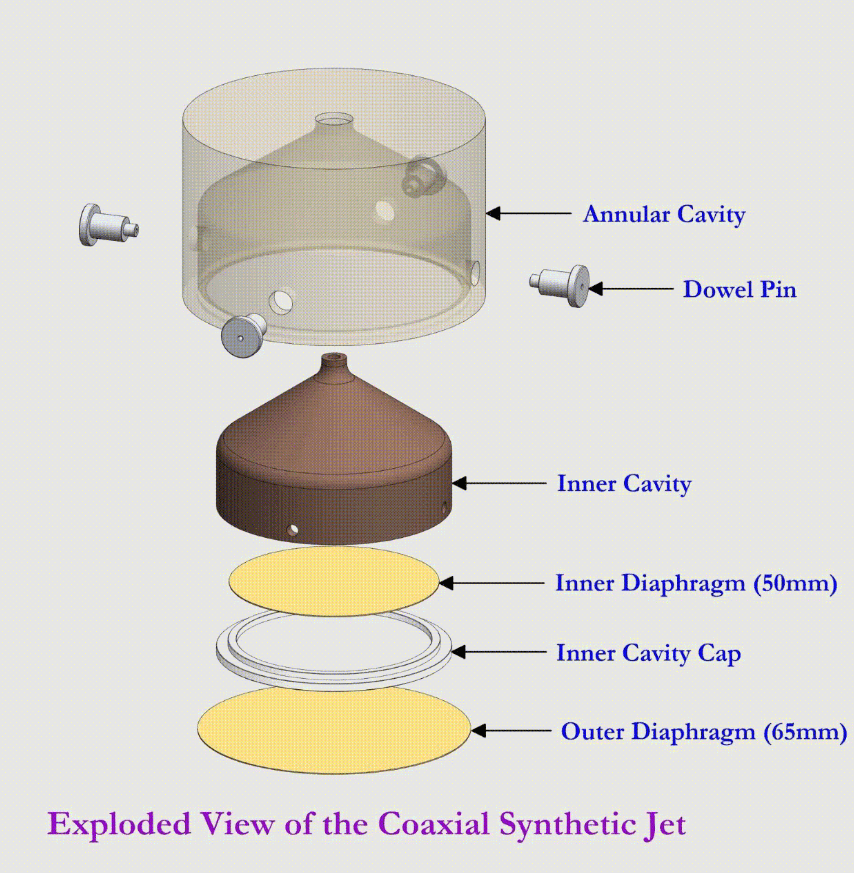

A System And A Method To Create And Modulate Coaxial Synthetic Jets

Indian Patent No - 202131047214

Background: Many engineering applications like, aerodynamics, electronics cooling, and process industries and combustion requires effective utilization of fluids. Such applications demand an active flow control technique to manipulate the flow field to achieve the desired effects like turbulence enhancement and vortices. Existing flow control devices have limited scope due to their ineffectiveness in manipulating the flow field to achieve these desired effects.

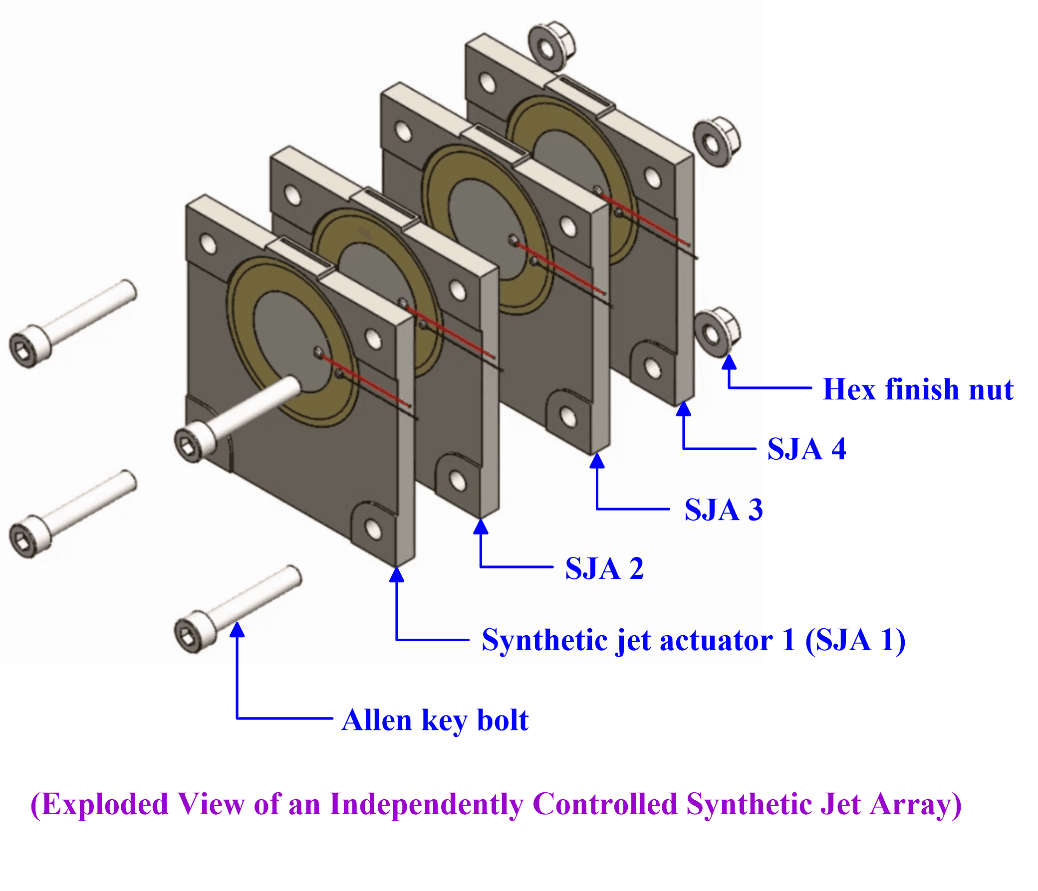

A system and method for focusing of jets

Indian Patent No - TEMP/E-1/38398/2023-KOL

Background: Many engineering applications like, aerodynamics, electronics cooling, and process industries and combustion requires effective utilization of fluids. Such applications demand an active flow control technique to manipulate the flow field to achieve the desired effects like turbulence enhancement and vortices. Existing flow control devices have limited scope due to their ineffectiveness in manipulating the flow field to achieve these desired effects.

A System and a Method for Multipoint Sensing

Indian Patent No - TEMP E-1/59888/2020/KOL

Background: Detection of vibration at multiple locations has applications in industrial operations, tracking of physiological motions for health monitoring and environmental surveillance. OTDR, FBG and classical interferometry techniques have been proposed in this regard. However, the OTDR and classical interferometric techniques are limited by reduced sensitivity with length of fiber while FBGs are temperature intolerant and lack scalability. Hence, more effective and reliable sensing and detection techniques are required.

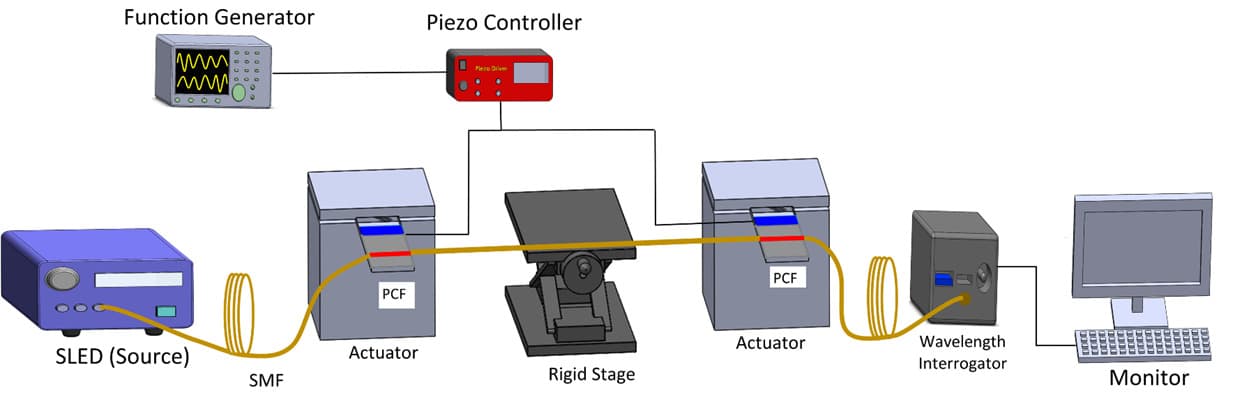

A Model Interferometer Based System to Improve Performance of Vortex Flow meter

Indian Patent No - E-5/320/2019/KOL

Background: Optical fiber-based vibration sensors are a potential class of technology. Their market value is rapidly increasing due to their high sensitivity and the potential to design versatile probes to detect various parameters. In practical applications, the performance of such sensor probes is affected by the external field noise and low amplitude of the external field. In order to improve their real time performance in complex environments, the modulation or conditioning of their responses is a definite solution. In this regard, methods based on spatial signal processing or phase noise cancellation have been reported. However, amplification, attenuation of noise components and filtering using a single system remained elusive.

A Rational System for Testing Resilient Modulus of Unbound Granular Materials

Indian Patent No - Patent Application Submitted

Background: Resilient Modulus (MR) of Unbound Granular Materials (UGMs) is a critical parameter in the Mechanistic-Empirical (M-E) pavement design procedure. In most countries empirical correlations are used to determine MR of unbound granular layers due to the complex, time- consuming and resource-intensive nature of Repeated Load Triaxial Tests (RLTT). Alternative set-ups such as Springbox, K-Mould and PUMA are available for determination of MR. But the confining pressure is not entirely user regulated in these set-ups as it is applied via spring or rubber. And none of the mentioned test set-ups consider the effect of subgrade stiffness on the MR of UGMs